How To Build A Shed Door With Window

Building a shed door should be kept simple, but how elementary a structure should you use?

Building a shed door can be a uncomplicated task, practice the basics correct and you will feel proud every time yous go in to your shed. The showtime part of this page shows y'all the types of shed door, the parts of the door and how they go together. I so show you lot how to build a shed door step past step, with pictures of a shed door that recently made.

Allow's get started with the different types of door and which is all-time to build.

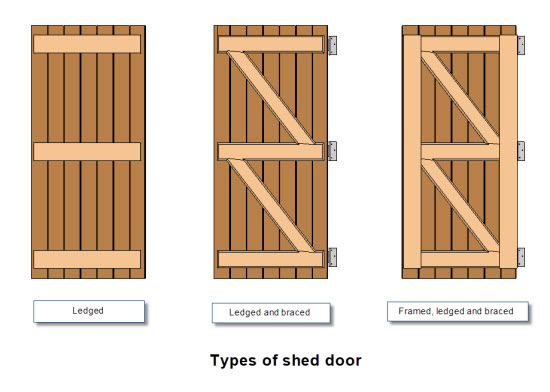

There are 3 levels of structure that you could opt for before deciding to go the whole hog and buy a set-fabricated door and frame.

These types of door are:

- Ledged

- Ledged and braced

- Framed, ledged and braced

A good remainder of ease of construction can exist achieved with the ledged and braced door

The uncomplicated ledged door has a tendency to drop over time. Due to expansion and contraction of the timber gravity takes a agree and eventually the door bolt won't line up with the keep on the frame.

The framed ledged and braced door is the strongest and most stable of the 3. The door is prevented from dropping by the diagonal braces and the frame around the perimeter helps to make the door more secure and prevent warping of the whole door. However this does come up at a toll of complexity. To make a good framed, ledged and braced door you will demand to construct mortise and tenon joints for the frame and braces.

A happy medium of the two is the ledged and braced door. This is the one that I show in the step past step building a shed door instructions farther downwardly this page. The braces stop the door from dropping/sagging and the ledges provide a good opportunity to set security bolts between the door and the frame.

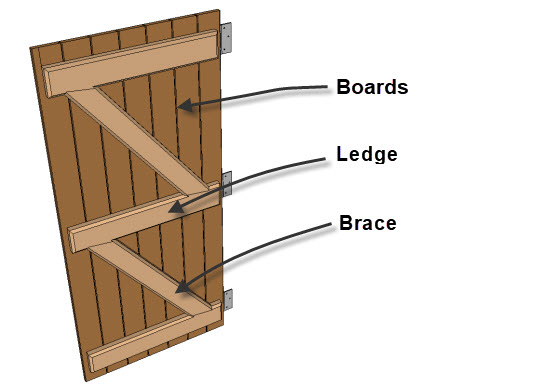

Then what are the main components of a ledged and braced door?

The three main components are:

- Boards - These class the face of the door

- Ledges - These are the horizontal boards

- Braces - These are the diagonal boards

`

Elements of a shed door

Elements of a shed door

If y'all are building a shed door at that place is a wide degree of combinations of thickness and blazon of materials that tin can exist used to construct each of these shed door components. Only mostly the thicker and better quality the timber the stronger and more than stable the terminal result will be.

It goes without saying that many commercially built sheds are built with thin material and of fairly minimal structure. They all work initially merely over time the lack of quality starts to show. Every bit the door drops, the boards warp etc.

So what materials should you apply to construct your shed door?

Allow'southward start with the boards that form the principal body of the door. These are often made from the same material as the residuum of the shed cladding for economy (only i blazon of material to order) and visual continuity (the door matches the remainder of the shed).

In the example below I departed from this convention to make a door that contrasted with the cladding of the shed. This dissimilarity came with a time and cost penalty (though I was very happy with the result).

The simplest type of board to use is the interlocking tongue and groove type. Equally these boards interlock there is no gap between them for draughts. Tongue and groove boards beginning at about 12mm thick (very thin) and go upward to effectually 20mm.

When ownership timber (of any type) exist aware of the difference between rough sawn and planed timber. Frequently suppliers will quote the rough sawn size (information technology is e'er larger) assuming that you know that the planed timber size will actually be smaller. This isn't a con fox or them being dis-honest it is just part of the process of taking timber from a tree to the finished log. However to the unititiated information technology can be confusing:

For cladding size timber :

I prefer rough sawn timber for cladding sheds for 3 reasons:

-

Firstly it is cheaper, planing timber costs coin so the rough sawn timber is cheaper per square metre.

-

It is thicker, by planing a section you take away some of its thickness every bit strength. Reducing a piece of timber from 16 to 12mm removes 25% of its thickness and twoscore% of its strength (strength is proportional to the square of thickness).

-

Finally crude sawn timber is better at receiving paint and stain than planed timber. The rough surface holds the paint ameliorate, is more absorptive and doesn't endure from compression of the fibres in the planning process. Paper by US Forest Products Laboratory - 'Forest properties affecting finish service life'

As you volition soon run across I used 20mm thick, crude sawn, foursquare border boards and then needed a cover strip to weather proof the gaps between the boards. This was part of my design, just one that added a little extra to the time needed to brand the door.

If y'all are edifice a shed door for the first time then I would recommend that you employ tongue and groove boards.

Ledges and braces

If you are using 20mm thick boards for the confront of the door then you could use the same timber for the ledges and braces. Only if you are using that skinny 12mm thick planed material I would recommend that you utilise something thicker like 32x45 for the ledges and braces.

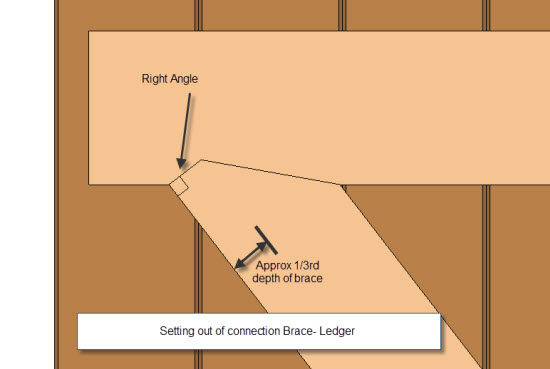

Connections between ledges and braces

In that location is no structural connexion betwixt the 2. The traditional method is to make a notch in the ledger equally in this sketch so that the caryatid is always in compression.

Setting out of the interface between a brace and ledge

Setting out of the interface between a brace and ledge

What connectors are used to connect the ledges and braces to the door?

Traditionally ledged and braced doors are nailed from the front. This works when fixing through thinner material into a thicker brace or ledge behind.

When fixing with nails like this then typically the nail lengh is 2.v times the thickness of the door facing material.

For edifice a shed door similar this yous will see that I opted to use screws and utilise them from the inside of the door. This meant that the fixings are protected from the weather and the forepart of the door is non damaged. Information technology also gives the front of the door a 'cleaner' appearance.

If you utilise a timber such as oak or sweet chestnut for building a shed door then you will besides need to use Stainless Steel screws as they are resistant to the acidic tannins in these forest.

Nosotros have now covered the basics of building a shed door

So let's become on with building a shed door

I mentioned before that it would definitely save you lot time to purchase set up cut boards, with a tongue and groove profile, but would it exist as much fun?

The boards that I used here were 20mm thick, rough sawn, waney border boards which are almost a waste material product from the saw mill that I bought them from.

The boards every bit bought were 'wet' and needed fourth dimension to air dry out (allow approximately 1 year per inch of thickness). To keep the boards relatively straight, stack them with timber spacers every iii-400mm and keep a weight on top while they dry out.

Laying out and assessing the waney edge boards

Laying out and assessing the waney edge boards

Cut the boards to width would normally exist done on a tabular array saw

For a pocket-size number of boards such every bit this it is slightly more fourth dimension-consuming - but relatively straightforward - to use a standard hand held round saw. Utilize a straight floor board equally a directly edge for the beginning cutting and and then make use of the width guide which is part of the saw's add-ons to cutting the contrary side.

When cutting the board y'all will demand to use your ain skill and judgement to cut off the sap wood while maximising the useful width of the board. It is also really helpful to audit the timber and see what features you lot desire to cut out or include.

You lot demand to cutting off the end checks and splits but there may be some interesting knot or grain features that you want to include.

The primary priority in my view is to maximise the width of boards accomplished.

Board clamped to demote and cut off the waney edge

Board clamped to demote and cut off the waney edge

Decide on the width and tiptop of your door

The dimensions of the door for this shed were 600x1800mm. I cut the boards to length and laid them out to piece of work out what I idea as the all-time arrangement.

Laying out the boards for the door

Laying out the boards for the door

When arranging the boards for building a shed door accept into business relationship the orientation of the growth rings. Due to the nature of the boards, the outside of the lath will expand and compress at a unlike rate to the inside, leading to an effect known as 'cupping'.

'Cupping' can exist mitigated by fixing the heartwood on the outside so that the screws/fixings clamp the board to the batten keeping it as straight as possible.

Close upwards view of finish grain. The lath nearest the camera has the heartwood facing to the outside. The board side by side to it is placed incorrectly with the heartwood facing inwards and will exist flipped over to minimise 'cupping'

Close upwards view of finish grain. The lath nearest the camera has the heartwood facing to the outside. The board side by side to it is placed incorrectly with the heartwood facing inwards and will exist flipped over to minimise 'cupping'

Arrange the battens and braces on the back of the door

I used iii boards beyond the back to course the ledges for this door. The ledges keep the face of the door directly and provide a connexion between each of the boards. Y'all will see that sometimes people endeavor to reduce the number of ledges to ii. This is a false economy in my view and makes the door less robust.

When building a shed door, the slope direction of the braces is important. Timber swells and contracts perpendicular to the grain but varies picayune dimensionally along the grain.

Having the braces sloping up from the lesser and centre swivel puts the brace into compression. This means that the weight of the door is trying to close the articulation all the time and button the brace into the housing.

If the brace was the other way up so the weight of the door would be trying to open the joint, which given enough time along with moisture and dry out cycles, would happen. Then the door would no longer be square and kickoff to sag.

Laying out the ledgers and braces on the back of the door

Laying out the ledgers and braces on the back of the door

Note:

When you accept a look at doors on commercial sheds you often run across that they take one brace sloping up and ane sloping downwards. I believe that this is to hedge their bets and so that they are guaranteed that at least one caryatid volition be effective whichever mode upwardly the door is hung.

One time yous have decided on the arrangement for the ledges and the braces, marking these on the boards and cut out the housings. Using a chisel and mallet is the easiest method to do this.

Building a shed door - Cutting in the braces with a mallet and chisel

Building a shed door - Cutting in the braces with a mallet and chisel

A concluding touch for the ledges and braces is to plane (or utilize a router) to add together a pocket-sized chamfer to each of the exposed edges. This increases the visual appeal of the elements and also reduces the possibility of splinters and splitting of the edges.

Fixing the door together

Use clamps to pull the boards together and likewise to hold the ledges and braces in position while you set up them in place. The traditional method of fixing the battens to the door was to nail from the 'front' of the door through the board and ledger.

The stop of the boom was then 'clenched' which means bashing the end of the blast over so that the nail couldn't exist removed. With the advent of modern fixings I choose to secure the battens and braces from the back of the door with screws, thereby giving the front end of the door a less cluttered await.

Close upward of brace and fixings. Note that holes for screws are pre-drilled and countersunk

Close upward of brace and fixings. Note that holes for screws are pre-drilled and countersunk

Remember to use stainless steel screws when working with sweet chestnut or oak. The natural tannins within the wood, which are responsible for the timber's durability, are acidic and promote corrosion in plainly steel fixings.

Moreover,sweet chestnut can be prone to splitting when relatively unseasoned so pre-drilling and countersinking the screw holes reduces the possibility of this happening.

Fixing the shed door hinges

Make sure you understand where the swivel pin sits in relation to the door opening so that you fit the swivel in the correct position. This will prevent problems further down the line when you come to hang the door.

Plumbing equipment the hinges

Plumbing equipment the hinges

Fitting the cover strips

If y'all are building a shed door out of the more normally available tongue and groove boarding so you tin can omit this pace.

Making a door from plain edge lath means that gaps will announced betwixt the boards dependent on the season of the year and the moisture content of the door. The cover strips that we added are to keep out the worst of the rain and wind. Though having a tongue and groove board or a loose tongue rebated between the boards is definitely an alternative solution.

Plumbing equipment the encompass strips

Plumbing equipment the encompass strips

I liked the appearance of the cover strips especially after seeing something like on a visit to my local pub ;-).

Pub door of similar construction with cover strips

Pub door of similar construction with cover strips

Finishing the door

With the door complete, apply a couple of coats of linseed oil or teak oil. These treatments soak into the fabric of the timber and add together to its natural durability. They besides brand information technology easier to recoat and maintain as dissimilar pigment they repel water and moisture does not get trapped behind them.

Completed door with glaze of linseed oil

Completed door with glaze of linseed oil

You lot will of course need some door article of furniture, a lock and/or a handle to secure the door. The best fittings that I have come beyond are the 'long throw' style locks.

These fittings apply a Euro-style cylinder and have a 20mm foursquare stainless steel commodities with a metallic housing that has sufficient tolerance to accommodate the sort of timber motion to exist expected on a shed.

I chose to brand a simple slide commodities out of timber for everyday opening and closing, with a more secure bolt for when the shed has contents that are to be left unattended.

Find out more about the different types of shed door latch here

Simple timber slide commodities

Simple timber slide commodities

Related posts:

- How to hang the shed door that you take just congenital

- How to straighten a sagging shed door

- What type of hinges will you use on your ledged and braced shed door?

- How to construct a really stiff shed door

Custom Search

Keep in touch with our monthly newsletter

Shed Building Monthly

Source: https://www.secrets-of-shed-building.com/building_a_shed_door.html

Posted by: trippcopievere.blogspot.com

0 Response to "How To Build A Shed Door With Window"

Post a Comment